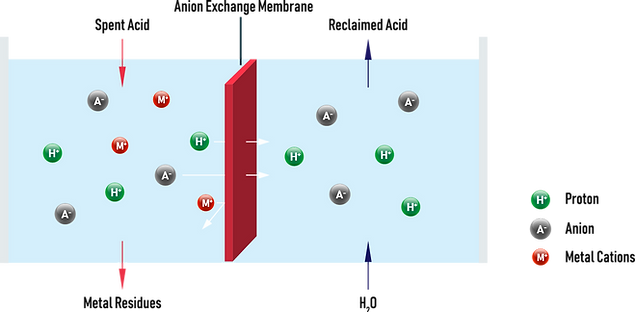

Diffusion Dialysis Anion Exchange Membranes Working Principle

Acid recovery via Diffusion Dialysis utilizes an Anion Exchange Membrane (AEM) as a semi-permeable barrier placed between a flowing water stream and a flowing acid stream which contains dissolved metals. The anion exchange membrane has a fixed positive charge located on its surface. These positively charged locations attract the negatively charged anions in solutions that come in close contact with the anion exchange membrane surface.

Diffusion Dialysis Anion Exchange Membranes main applications for acid recovery:

-

Iron & Steel Pickling

-

Stainless Steel Passivation

-

Chemical Machining

-

Stainless Steel Pickling

-

Acid Etching

-

Metal Finishing

... and many more.

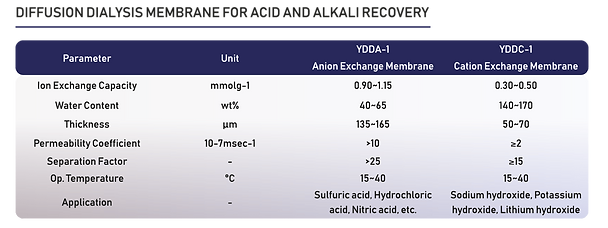

Diffusion Dialysis Anion Exchange Membranes Specifications

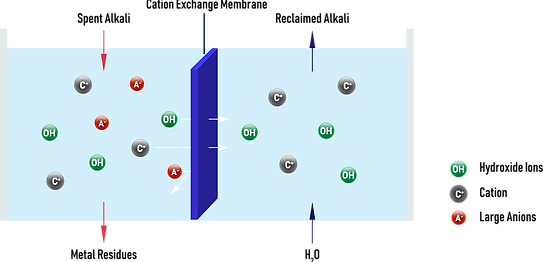

Diffusion Dialysis Cation Exchange Membranes Working Principle

Alkali Recovery via Diffusion Dialysis (DD) is a process used to recover and recycle alkaline substances, such as sodium hydroxide (NaOH) or potassium hydroxide (KOH), from industrial waste streams, especially in industries like metal finishing, pulp and paper, and textile manufacturing. This process helps factories to reduce and recycle their alkaline waste and lowers their disposal and costs of newly produced alkali.

Diffusion Dialysis Cation Exchange Membranes main industrial applications for alkali recovery:

-

Paper

-

Leather

-

Printing & dying

-

Tungsten ore smelting

-

Man-made fiber industries

... and many more.

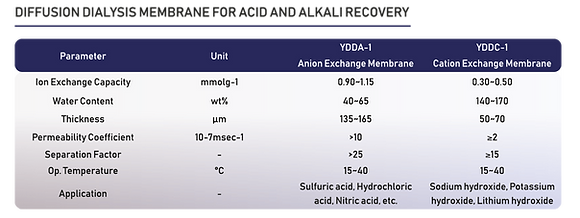

Diffusion Dialysis Cation Exchange Membranes Specifications

Diffusion Dialysis Membrane Layers Advantages

Diffusion dialysis (DD) provides an alternative, compatible and prospective method for acid and alkali recovery.

The most outstanding advantages of DD are the clean nature, low consumption of energy, low installation and operating cost.

Besides, the integrations of DD (particularly for acid recovery systems) with other methods can increase the processing capability and efficiency, so that the acids (even with low concentration) and the metal salts can be successfully recovered.

1. High recovery efficiency in industrial applications

2. Minimal energy consumption with concentration driven principle

3. Wide applicability for wastewaters and spent chemicals